Visit our office

Address

Plot # 2 , Street # 1, Survey # 88, Golden Town Shahrah-e-Faisal, Air Port, Karachi.

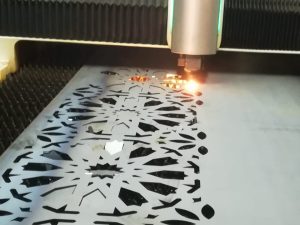

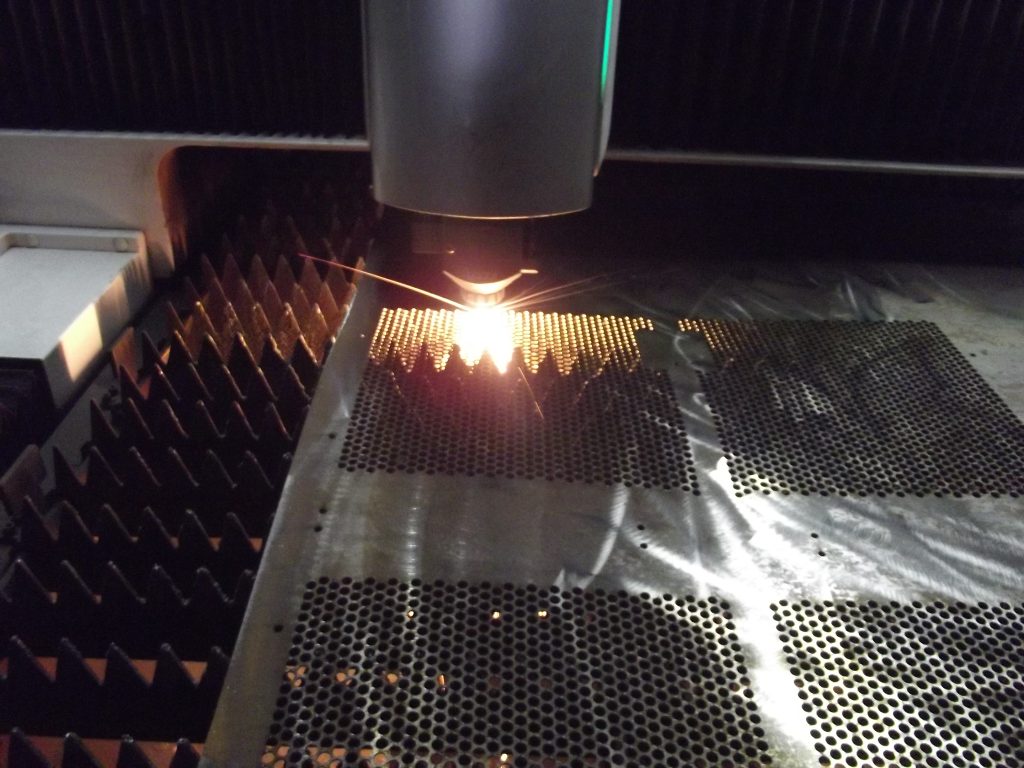

CNC Laser Cutting Services in Pakistan Power Engineering | Pengpk

Power engineering qualified and manufacturing services provider all over Pakistan. We are a Leading metal sheet cutting service provider with the latest model of CNC laser cutting (Wi-Fi connected) including sheet cutting and Tube cutting. We use advanced technology CNC Laser Cutting Services in Pakistan and advanced cutting process in our process.

In laser cutting a focused laser beam radiating with high energy density is used as a cutting tool for the thermal cutting process on the workpiece of metal. Laser cutting use on-oxidizing gas (N2, Air) to cut or reactive metal including stainless steel titanium, aluminium various metals, non-metal sheets and composite materials.

Some Technical Specification of Our CNC Laser

- MS, GI, SS, Copperplate and tube/pipe cutting, perforation, mesh making, filter making, panels DB opening cable tray perforation, and all other designs on sheet and Pipe as client requirement

- MS sheet Cutting thickness 1mm to 16 mm

- Galvanized sheet Cutting thickness 1mm to 8 mm

- Aluminum sheet Cutting thickness 1mm to 8 mm

- Brass sheet Cutting thickness 1mm to 6 mm

- copper sheet Cutting thickness 1mm to 6 mm

- Cutting perforation tube/pipe 20-200mm dia 8mm thickness

- Machine Bed size for sheet plate 10 feet x 5 feet (we can work at this size sheet )

- Machine Bed size for sheet plate 10 feet x 5 feet (we can work at this size sheet )

Advantages of Laser Technology

- High accuracy

- Excellent cutting quality

- High speed working

- Compared to other thermal cutting processes, laser produce a very narrow heat effect at objective

- Minimum deformation of the cut sheet because of the very low level of heat applied

- It can work at any metal

- Supporting 2D and 3D cutting, mainly 2D cutting

- Supporting various file formats, including G-code file, IGS file, NC file, DXF file, PLT file, ENG file, etc

- It can make any size and shape perforation/holes

- Supporting preprocessing imported objects

- Providing kinds of pulse modulation signals to mate with a different laser machine and to adjust duty ratio according to cutting speed

- Supporting layer function and technics such as cutting with film, corner loop, cutting at a fixed height

- Supporting various piercing methods such as direct pierce, incremental pierce, segmented pierce, three-segment pierce, and pre-pierce; besides, we can set laser power, frequency, gas type, and pressure separately in piercing and cutting

- Supporting scan cutting, including line scan, arc scan, and scan on the LED text

- Supporting tube cutting function

Services Provided

- Plasma cutting

- Fiber laser cutting

- Flame cutting

- Fiber laser engraving and marketing

- Metal fabrication

Why Power Engineering?

- Supporting preprocessing imported objects

- Qualified and Specialized Staff for laser cutting

- years manufacturing experience and the working experience of the worker

- One-stop Service: We will manage to manufacture, QA, deliver products from Our factory to you directly

Flexibility

Laser cutting doesn't require the changing of tools for different cuts and the Same setup is suitable for cutting a lot of different shapes within the same material thickness.

In-time Delivery

Power engineering is always ready to deliver you Excellent cutting quality services in Pakistan. With the delivery in time we are leading the market.

Quality

Using the proper setup, laser cutters only leave a slight burr. It does not affect the design. It depends on the material, its thickness and other factors.

Expertise

We have specialist operator is a must to make the most of a laser cutter's potential. The proper setup makes sure the cutting quality is up to the standard people expect from this technology.CNC Laser Cutting Services in Pakistan